Click search

Click search

product description: The vacuum sizing long rack type storage truck is composed of height adjustment device, pipe size adjustment device, roller group stand, auxiliary climbing device, etc. When in use, adjust the roller group stand to the appropriate position according to the specification tube, and adjust the height. The device is adjusted to a suitable height so that the conveyed pipe is alway

more

Chipless cutting saw for vacuum sizing production lineThe chipless cutting saw is composed of a frame, a moving body, a rotary assembly, a clamping mechanism, a cutting tool device, and a PLC electric control system. During cutting, after the product is clamped by the clamping mechanism, the moving body moves backward on the rack rail under the action of traction. On the rotary assembly, the cutti

more

Track-type traction, the tracks are symmetrically distributed in the axial direction, and the clamping and loosening are electrically adjusted by the slider screw. Silicone material, which can better clamp the pipe during traction. The frame is made of profiled steel. The frequency conversion control is adopted throughout the process. The traction is stable and can work synchronously with the mach

more

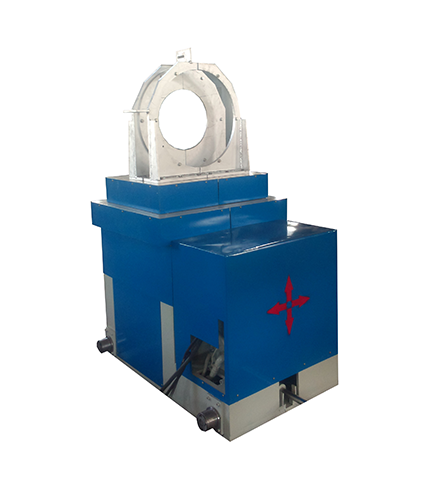

Vacuum sizing box product introduction:The vacuum sizing box plays a key role in sizing cooling in the vacuum pipe production line. The box is made of high-quality anti-corrosion stainless steel material, the spray system uses ABS atomizing nozzles, full PLC control, with automatic inlet and drain, automatic water level control, automatic water temperature control, dual channel water supply, water

more

Pipe end bevel grinder: Use PE bevel system to bevel the pipe end for welding construction and anti-corrosion repair during pipe laying. It consists of PE beveling machine and beveling elevator. PE beveling machine is composed of front and rear traveling trolley, wire brush device, pneumatic system, electrical control cabinet, etc. The bevel elevator is composed of a frame, a rubber wheel and

more

Spray room: After the steel pipe is coated with 3PE, it enters the cooling room for cooling and shaping. The cooling chamber is equipped with a lifting spray device, which can be adjusted according to the size of the 3PE pipe diameter. According to the 3PE products with different pipe diameters, the cooling can be achieved by controlling the flow. The drive parts in the cooling chamber are equippe

more

Gluing + PE winding extruder: Adhesive winding: Due to the poor adhesion between the polyethylene layer and the sintered epoxy coating, the adhesive is used to improve the bonding of the sintered epoxy coating and the polyethylene layer with two different polar materials. The adhesive must be applied during the gelation of the epoxy powder.

more

Powder spraying chamber: The workpiece enters the spray gun position of the powder spraying chamber through the conveying chain to prepare the spraying operation. The electrostatic generator releases high voltage static electricity (negative electrode) to the space of the workpiece through the electrode needle of the spray gun nozzle. The mixture of powder and compressed air sprayed from the nozzl

more

The pipe laying machine :The pipe laying machine mainly plays the role of laying the finished product pipe in the one-step production line. When the unit is running, it can realize multi-stage speed operation and fast laying of the finished product pipe through frequency conversion and speed regulation, and can realize fa

more

Correction machine: The function of the correction machine is to control the thickness of the foamed layer relative to the outer surface of the steel pipe to be uniform, thereby ensuring the overall performance of the product. When working, the thickness of the foamed layer is sensed by a digital probe. Once the thickness deviation of the foamed layer occurs, correction can be made in time, which

more

Foaming machine: The foaming agent is sent between the steel pipe and the anticorrosive layer to play the role of heat preservation during product use. When the foaming machine is running, the materials in the two tanks are pressed into the foaming gun through the proportional metering pump. The foaming gun simultaneously conveys high-pressure air to drive the mixture between the anticorrosive lay

more

Mould: It adopts a right-angle multi-layer spiral shunt structure. This structure reduces the extrusion pressure, uniform plasticization, and stable high-speed extrusion molding. All indicators of the pipe have reached national standards. The structure is a new type of olefin combination, the wall thickness of the pipe is uniform, the inside and outside are smooth, there are no bumps or scars, the

more

Hebei Xinruide Pipeline Equipment Co., LTD., signed Qingdao Haixi Plastic Machinery Co., LTD. 150 line elbow equipment in October 2024. Hebei Xinruide Pipeline Equipment Co., LTD., as an old customer of Qingdao Haixi Plastic Machinery Co., LTD., thank you for your trust and support. With the unremitting efforts of all the staff of the company, the car was loaded and shipped on January 5, 2025, and

Hebei Xinruide Pipeline Equipment Co., LTD., signed Qingdao Haixi Plastic Machinery Co., LTD. 150 line elbow equipment in October 2024. Hebei Xinruide Pipeline Equipment Co., LTD., as an old customer of Qingdao Haixi Plastic Machinery Co., LTD., thank you for your trust and support. With the unremitting efforts of all the staff of the company, the car was loaded and shipped on January 5, 2025, and

The Russian customer ordered the 120-33:1φ110-710 vacuum sizing production line of Qingdao Haixi Plastic Machinery Co., LTD in February 2024. Due to our company's long-term adherence to technological innovation, adhere to the quality of enterprises, adhere to the integrity of service, and continue to win the wide recognition of foreign investors, Qingdao Haixi brand image has gradually established

The Russian customer ordered the 120-33:1φ110-710 vacuum sizing production line of Qingdao Haixi Plastic Machinery Co., LTD in February 2024. Due to our company's long-term adherence to technological innovation, adhere to the quality of enterprises, adhere to the integrity of service, and continue to win the wide recognition of foreign investors, Qingdao Haixi brand image has gradually established

The Russian customer ordered the 120-33:1φ110-710 vacuum sizing production line of Qingdao Haixi Plastic Machinery Co., LTD in February 2024. Due to our company's long-term adherence to technological innovation, adhere to the quality of enterprises, adhere to the integrity of service, and continue to win the wide recognition of foreign investors, Qingdao Haixi brand image has gradually established

The Russian customer ordered the 120-33:1φ110-710 vacuum sizing production line of Qingdao Haixi Plastic Machinery Co., LTD in February 2024. Due to our company's long-term adherence to technological innovation, adhere to the quality of enterprises, adhere to the integrity of service, and continue to win the wide recognition of foreign investors, Qingdao Haixi brand image has gradually established

The Russian customer ordered the 120-33:1φ110-710 vacuum sizing production line of Qingdao Haixi Plastic Machinery Co., LTD in February 2024. Due to our company's long-term adherence to technological innovation, adhere to the quality of enterprises, adhere to the integrity of service, and continue to win the wide recognition of foreign investors, Qingdao Haixi brand image has gradually established

The Russian customer ordered the 120-33:1φ110-710 vacuum sizing production line of Qingdao Haixi Plastic Machinery Co., LTD in February 2024. Due to our company's long-term adherence to technological innovation, adhere to the quality of enterprises, adhere to the integrity of service, and continue to win the wide recognition of foreign investors, Qingdao Haixi brand image has gradually established

In the process of use, good maintenance and maintenance can extend its service life and ensure its stable performance. Here are some care and maintenance tips:

MORE+Qingdao Haixi Plastic Machinery Co., Ltd. carefully built equipment production line, has been officially put into operation at the customer! This seamless bend 90, 120, 150 production line, after rigorous design, precision manufacturing and rigorous testing, finally in the customer Cangzhou Guangsen Pipe Industry Co., Ltd. factory radiates a strong vitality. Its official operation not only mark

In the process of use, good maintenance and maintenance can extend its service life and ensure its stable performance. Here are some care and maintenance tips:

MORE+Release time:2024-10-19

Tell:15192788777

Tell:13905427188

No.1, Haixi Road, Beiguan Industrial Park, Jiaozhou City, Shandong Province

Haixi main production3pe,Vacuum sizing,One step method,Excellent performance,Safe and reliable, welcome to call~

Hot Keywords:Vacuum sizing Vacuum sizing dynamics