24-hour hotline for enterprises

24-hour hotline Click search

Click search

Vacuum sizing dynamics NEWS

3PE anticorrosive steel pipe need to do some tests

source:www.qdhxsj.com Release time:2023-05-09 Return list

3PE anticorrosive steel pipe need to do some tests

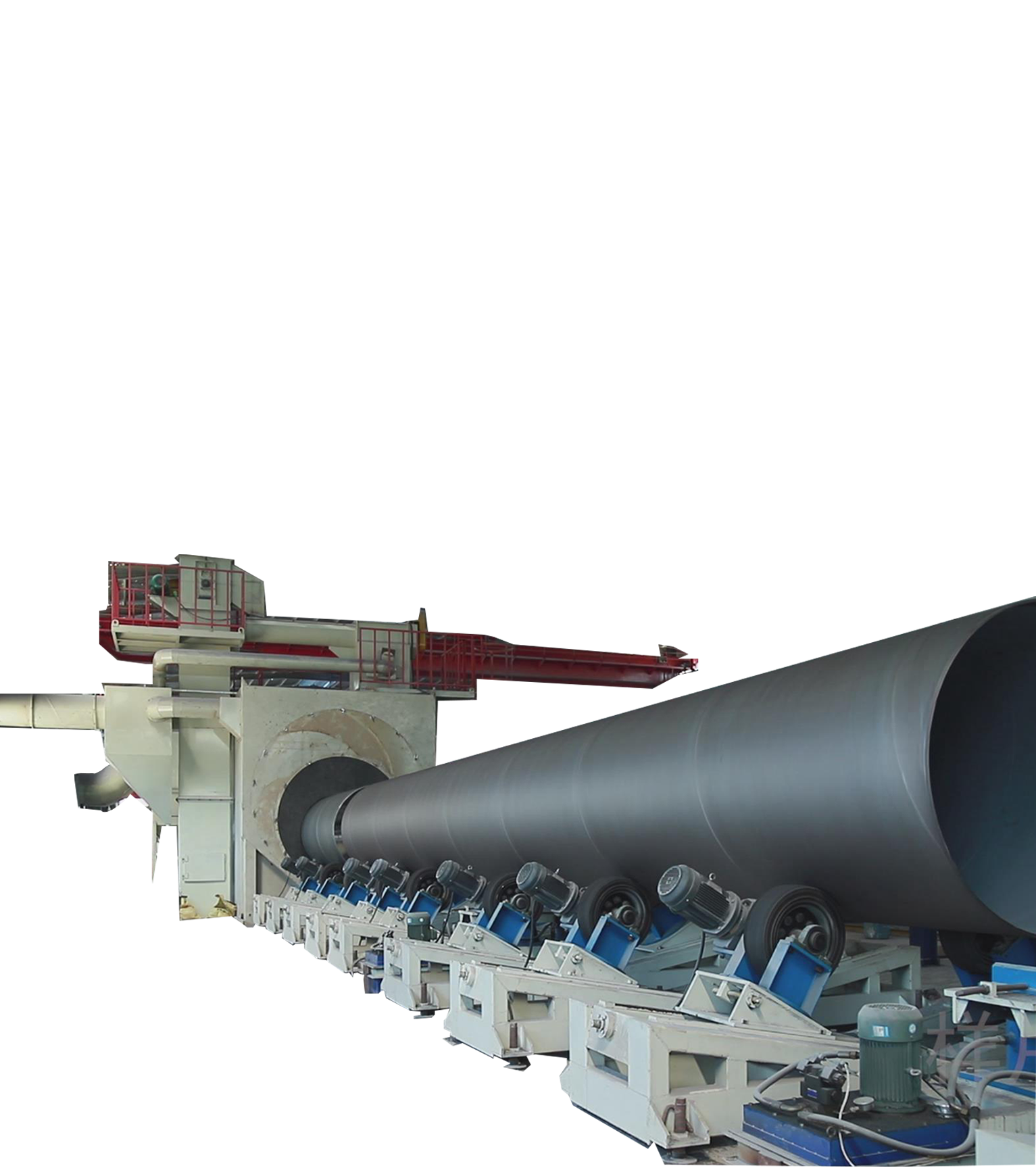

3PE anticorrosion is a kind of anticorrosion outside the pipeline. 3PE anticorrosive steel pipe with high sealing. Long time operation can greatly save energy, reduce costs and protect the environment. Anticorrosive process

Every link in the code should be tested.

First, check the surface of the bare pipe for oil, pit, layer, weld shape, steel pipe height and other shortcomings

Two: After rust removal, check the depth of anchor grain (anchor grain shape can be seen more finely) and cleanliness (Sa2.5).

3: After the completion of 3PE corrosion test: spark leakage test, peel strength (60°C and room temperature), FBE thickness and the total thickness of the corrosion layer; Laboratory cathodic peel for 30 days

24 hours, indentation strength, bending strength and immersion for 1000 hours.

Four: discharge detector can be used for discharge detection. The device adopts digital circuit control and pulse generation principle. Unique single key switch, charging automatically into the charging state.

Digital circuit structure makes the display value more stable, high voltage pulse detection more stable. The aluminum alloy shell makes the machine more beautiful and durable.

Related articles

News navigation

Contact us

Address: No.1, Haixi Road, Beiguan Industrial Park, Jiaozhou City, Shandong Province

(Add: No.1,Haixi Road, Beiguan Industrial Park, Jiaozhou Shandong China.)

H.P:15192788777

Website:Http://www.qdhxsj.com ;

E-mail:haixisj2007@163.com

15192788777

15192788777